18 May The 8 Interesting Styles Of Scaffolding For Every Worksite and Situation

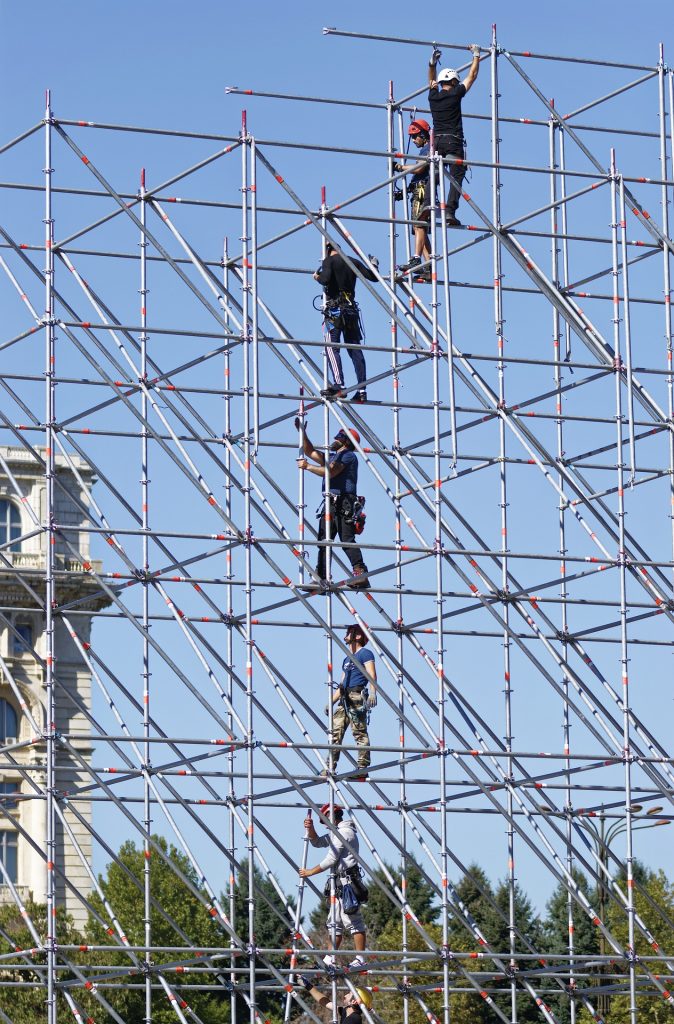

Scaffolding is far and away one of the most important aspects of any construction site, often being one of the first proponents purchased or rented when construction begins. It provides ample protection for the public, stability and safety for the workers and an all-round professional look for the company.

Each type of scaffolding will be dependent on the work needing to be done, differing styles cater to differing jobs and it can seem overwhelming to determine at first, we have cultivated a list of 8 that have specific functions for any worksite or situation.

1. Single Scaffolding

Let’s start with the basics, this particular build is used mostly for brick masonry jobs and is comprised of a singular pane with support beams. It’s typically around 1.2 metres from the ground and is the classic style that has been utilised for many years, but it’s not always the most stable of the bunch.

2. Double Scaffolding

Double as the name implies refers to the double layered system in the setup. Comprised of the previous entry due to its extensive support beams and double layer of ground support. This style is typically used in stone masonry jobs or where more instability could be apparent. The sturdiness has lent it to be a superior safety measure than the single alternative.

3. Kwikstage Scaffolding

You can’t talk about the gear without mentioning Kwikstage. This is one of the more popular styles to come out of recent years due to the inherently easy method of setting up and dismantling and its incredibly sturdy build utilising galvanised steel. The longevity of the metal along with its versatility in terms of being appropriate for large or small jobs with equal levels of ease is the foundational reason for its infamy in the construction industry.

4. Patented Scaffolding

We now come to the patented variety, otherwise known as towers depending on the supplier are made of a steel material. They have unique coupling and frames that allow construction workers working at a greater height to reach a little higher with ease and are purchased premade for extra convenience.

5. Steel Scaffolding

We get to the workhorse variety of materials and builds with the steel. While inferior alternatives utilise timber or bamboo as a building material, the steel variety has unprecedented tensile strength and durability to allow for extra security and assured confidence. Built similarly to the single variety, this style is favored in most building situations as a stock standard safety measure.

6. Aluminium Scaffolding

The aluminium variety is rising in popularity with workers in the painting and electrical fields due to the very portable nature of the material and its overall sturdiness ratio with the lightness. It’s not recommended for heavy-duty work however as the steel alternative is much sturdier but not as portable.

7. Trestle Scaffolding

The trestle varieties are primarily utilised in indoor settings for painting or electrical works as well. Being supported on a tripod-type setting with ladders to allow easy changing of height which suits them perfectly for the jobs specified earlier.

8. Cantilever Scaffolding

Our final style of scaffolding is the cantilever variety which is an ‘in case of emergency’ style due to the various checks and potential hazards that can be easily associated if the proper checks are not completed before using. This in turn extends the time taken to set them up and can inhibit progress if avoidable. The situations where cantilever methods are needed are when there are obstacles impeding the support structure on the ground and a wall-type support must be introduced.